#How solvent recycling

Text

How solvent recycling saves 1 Million gallons of solvents a year with this one simple machine

Today, many businesses are going environment-friendly, including large industries. Due to strict regulations, companies are forced to make amendments in their manufacturing and recycling process that can have a significant impact on the environment and the working conditions.

Recycling solvents help not only the environment but also the industries to save a lot of investment in buying new solvents every time. For this, industries need to focus on the best solvent recycling machines available in the market. It will help them reduce the introduction of hazardous waste into the surroundings and solvent costs.

Though there are many solvent recycling machines available in the market, how can you find the right one for you? So cut to the chase, you can try SW8, a powerful solvent washer model, a perfect solution to your solvent recovery problem.

Here, we will help you understand what this model is and how you can install it within your parameters to help you grow your business.

But before that, we will help you understand solvent recycling and its core benefits.

Introduction to solvent recycling

Solvent recycling arose from the need to keep the environment safe and clean. Everyone knows how industrial waste can be hazardous for every living being. Solvent recycling simply means recycling the solvents produced throughout the manufacturing process.

This process cleans the contaminated solvents and helps the industries to reuse them in the further manufacturing process without depending on new solvents. This way, the cost of buying new solvents gets reduced, and you can keep the environment clean by reusing the solvents.

If you have an on-site solvent recycling system, then you can experience significant benefits than having an off-site solvent recycling system. Thus, most companies are trying to move their solvent recycling facility to their nearest parameters for more benefits.

It is estimated that the solvent recycling market will grow in the coming years, as shown in the below chart.

Why should you recycle solvents?

If you are not recycling your solvents, you could be under the government’s radar for not following the regulations within your area. Not following the recycling standards will not only degrade your brand reputation but also degrades the environment quality.

If you properly recycle the solvents, you can easily lead to better quality control. It will become more effective with an on-site solvent recycling machine SW8, then will make your recycling process more accessible.

But the benefits do not end here. Below are some considerable benefits that you can avail of by using solvent recyclers.

It has eliminated the dependency and need for new solvents, thus reducing solvent costs.

You will see significant results within months.

It helps you manage the on-site storage of waste.

It simplifies the regulatory reporting process.

With the current techniques, tools, technology, and advanced machines, recycling solvents within premises have become more accessible.

What is SW8 Solvent Recovery System?

Most companies might not be aware of this fantastic and powerful solvent recovery system that can help your industry to manage on-site hazardous waste. It is designed to fit within every type of premises easily.

This machine comes with the following specifications.

Process Rate: 8 Gallons/Day

Boiling Range of Solvents: 100F – 375F

Utilities Required

Electrical: 240V, 1 Phase, 20 amp

Water: 1 GPM

Dimensions

Length: 36 in

Width: 24 in

Height: 48 in

Weight: 425 Ib

How do SW8 works?

If you are new to SW8 solvent recycling machine and wondering how to operate it, then you must be aware of the simple steps below. This machine has a simple start button that you can press after filling it with the desired solvent you want to clean.

This machine offers various features that you can use to simplify the overall recycling process so that you won’t be worrying about having extraordinary human resources to handle this machine.

Below are some features that you will experience while using SW8.

You can quickly process a batch of 8 gallons.

You can set an automatic timer to shut down the recycling cycle at the end.

You can set the distillation system at an appropriate height.

You can easily open the lid with its tilt-back feature.

Not only this, it is a highly safe and secure facility to be operated by anyone. SW8 is a closed-loop system offering features such as an automatic heater to control excessive high and low temperatures and a stainless steel box with indicator lights to control the panel.

If you know the market well, you can experience how the technology has evolved to enhance the efficiency and viability of the solvent recycling process. Not only this, you will experience more features and advancements in the coming years.

Most solvent Recycling Equipment uses a distillation process that simply extracts the sand particles and carbon components from the produced solvent, making it feasible to be recycled back to reusable components. You can recycle various solvents that will eventually lower the cost of new solvents and decrease disposal difficulties.

Conclusion

An overall picture says that solvent recycling reduces your investment in solvent purchases and waste and reduces the environmental impact. The process of solvent recycling and recovery reduces the disposal costs, including buying fresh chemical purchases and storage costs. It results in having a positive impact on the environment.

There is no doubt how a solvent recovery process and machine can improve the brand quality of your business. Companies are moving forward with the safe environment approach, attracting top clients.

This way, you can easily enhance the safety standards and produce products economically. You can leverage consistent supply with an on-site solvent recycler system. So go for SW8. Go green!

#solvent recycler system#SW8#Solvent Recovery System#recycle solvents#Solvent recycling#How solvent recycling#Solvent#Solvent Waste Management

0 notes

Text

Researchers at Chalmers University of Technology in Sweden have developed an environmentally friendly method for recycling and purifying metals. Using gold earrings from a pawnshop in Gothenburg and biodiesel from the nearest filling station, the discovery could change an industry that is currently dependent on large amounts of fossil oil.

"Pure metals have a number of uses in a modern society, not least for the development of green technologies. Our research shows how the metal industry can accelerate the transition from fossil to bio-based solvents," says Mark Foreman, Associate Professor of Chemistry at Chalmers.

Gold is not only a precious metal that is a symbol of wealth in jewellery and gold bars. A regular smartphone contains slightly more than 0.03 grams of gold, and the metal is found in most of the everyday electronics we have around us. It is also important in components for the aerospace industry. For many applications, gold is mixed with other metals, which then need to be removed when the valuable gold sheet is to be recycled. In this process, organic solvents, such as fossil diesel, are used.

Read more.

#Materials Science#Science#Gold#Biomaterials#Recycling#Metals#Chalmers University of Technology#Reactions

19 notes

·

View notes

Text

Good News - April 22-28

Like these weekly compilations? Support me on Ko-fi! Also, if you tip me on here or Ko-fi, at the end of the month I'll send you a link to all of the articles I found but didn't use each week - almost double the content! (I'm new to taking tips on here; if it doesn't show me your username or if you have DM's turned off, please send me a screenshot of your payment)

1. Millions Of Maggots Donated To Charity In Honour Of The Maggot King

“[Blizzard Entertainment] donated millions of maggots to Tiggywinkles UK, a leading wildlife hospital, […] in honor of Duriel, the Maggot King, a notorious character in the Diablo series. […] This significant contribution is expected to feed the patients at Tiggywinkles for two years.”

2. New circuit boards can be repeatedly recycled

“A team led by researchers at the University of Washington developed a new PCB that performs on par with traditional materials and can be recycled repeatedly with negligible material loss. Researchers used a solvent that transforms a type of vitrimer—a cutting-edge class of sustainable polymers—to a jelly-like substance without damaging it, allowing the solid components to be plucked out for reuse or recycling.”

3. How a Cloned Ferret Inspired a DNA Bank for Endangered Species

“This black-footed ferret (Mustela nigripes) [is] the first endangered species in the U.S. to ever be successfully cloned […] from [a] cryogenically preserved cell line, obtained from a ferret named Willa, who lived in Wyoming in the 1980s. [… T]he FWS [is now] on a major project to cryogenically store tissue from every endangered species in the U.S., [… as] “an insurance policy against future loss of biodiversity in the wild.””

4. Maine Signs Trans And Abortion Sanctuary Bill Into Law, Despite Violent Threats

“[The new law] states that criminal and civil actions against providers and patients are not enforceable if the provision or access to that care occurred within Maine’s borders, asserting jurisdiction over those matters. It bars cooperation with out-of-state subpoenas and arrest warrants for gender-affirming care and abortion that happen within the state.”

5. $70M for Fish Passage Projects Address Climate Resilience, Strengthen Local Economies

“The Department of the Interior today announced more than $70 million […] that will improve fish passage around […] barriers fragmenting the nation’s rivers and streams [… as an] “investment to restore our nation’s rivers and streams, safeguard endangered fish species, protect Indigenous subsistence practices and provide communities with increased opportunities for outdoor recreation and economic growth,” said Secretary Deb Haaland.”

6. A Golden Age of Renewables Is Beginning, and California Is Leading the Way

“California—the fifth-largest economy in the world—has experienced a record-breaking string of days in which the combined generation of wind, geothermal, hydroelectric and solar electricity has exceeded demand on the main electricity grid for anywhere from 15 minutes to 9.25 hours per day.”

7. Collaborative conservation efforts keep lake sturgeon off the endangered species list

“The Service’s 12-month finding [that these sturgeon are not endangered] shows ongoing management efforts, such as fish stocking, have contributed to the conservation and resiliency of the species. “Today’s announcement shows the power of collaborative conservation and the impact it can have for species like the lake sturgeon,” said Midwest Regional Director Will Meeks.”

8. French municipalities bordering Luxembourg to offer free transport to commuters

“Luxembourg is the only country in the world to offer entirely free public transport. […S]ix French communities located near the border and many of whose residents work in Luxembourg have decided to band together and also offer a free shuttle for daily workers. […] Last year, governments in the two countries said they would work to increase train services to run every 10 minutes between Metz and Luxembourg City by 2030. There’s also a plan to extend Luxembourg City’s tram service to reach all the way to the border – a trip that would take only 30 minutes when ready.”

9. Solar is about to get a lot more affordable for low-income households

“The EPA granted 49 state and territory awards totaling $5.5 billion, six tribal awards worth more than $500 million, and five multistate awards amounting to $1 billion. Together, the awards cover all 50 states, Puerto Rico, and the District of Columbia. All of the funding is dedicated to low-income and disadvantaged households.”

10. Amsterdam will cover cost of changing one's gender on documents

“[T]he city’s residents will be able to change the gender on their birth certificate and Basic Registration of Persons (BRP) free of charge. [… T]he local government will also reimburse (part of) the costs of a new passport, identity card or driver's license.”

April 15-21 news here | (all credit for images and written material can be found at the source linked; I don’t claim credit for anything but curating.)

#good news#hopepunk#bugs#tw bugs#diablo#wildlife#technology#recycling#ferret#cloning#dna#endangered species#trans#abortion rights#abortion#law#transgender#fish#renewableenergy#solar#geothermal#electricity#sturgeon#conservation#nature#france#public transit#low income#lgbtq#lgbtqia

2 notes

·

View notes

Text

youtube

There are SolarPunx right know!

CARRY ON SCREENING is a long established screen printers specialising in ethical campaign and tour merch.

Located in a disused quarry on Cloud Hill, In Temple Cloud Somerset Carry On Screening is proud to be part of Rockaway Park, an ever expanding community of diverse and interdependent talents.

Our studio has been built using recycled and repurposed materials.

We draw our electricity from Rockaways solar panels affixed to the studios roof, and when necessary from Ecotricity who supply green energy.

We only print or supply Fairwear Foundation approved garms and work closely with our supplier of choice NO SWEAT a grassroots campaign that builds solidarity among workers worldwide. Their garms are made in a workers' initiative in Bangladesh called Oporajeo, set up by the survivors of Rana Plaza and the conditions they have established provides an example of just how the garment industry should be run.

All of our inks are water based, and our ink of choice is Permaset as none of their range contain contain ozone-depleting chemicals such as CFCs and HCFCs, aromatic hydrocarbons or any volatile solvents. They are also Vegan and GMO Free. We also operate a paperless and zero waste policy wherever possible.

We enjoy working alongside various bands, brands, campaigns and artists who hold a similar vision of collaboration and collectivism and are advocates for social change....

If this is you please get in touch.

9 notes

·

View notes

Note

Hi, I saw your comment about rayon and how it can be made from the by products of other processes, which is extremely cool… I was wondering if you have any advice you’re willing to give on finding the more sustainable rayon?I’ve been concerned about using bamboo because I read that it uses some very toxic chemicals during production and some factories that produce it have polluted rivers and communities nearby.

I have eucalyptus yarn which is apparently produced in a safer manner (a closed loop system iirc?) and feels amazing, but I’d love to hear if you’ve got any other tips or recommendations please!

Hi! Aw, thanks for reaching out. I think this is the first time I've had anything I've written get this much traction!

I'm gonna preface by saying that my formal professional experience around textile science is one course, so there's likely people who can speak on this better than me, but I did some digging and got you some sources for yourself.

So rayon is a class of fabrics with a number of different 'makes', and every different name represents a different process. Sometimes that difference is just the base material used (lyocell is made of eucalyptus trees and modal is made of beech trees for example, but both use the same method of manufacturing, which I'll touch on). Sometimes the difference is the method of manufacturing. Tencel brand rayons (the two I mentioned above) have a different manufacturing process to viscose or acetate. So if you know what 'type' of rayon your material is, that'll inform most of your buying decision.

Rayons are made by dissolving plant material in chemical solvents, and then extruding that plant goo through another chemical bath that restabilizes the goo into yarn filaments that can be worked with.

This basic process is universal for all rayons, but within those steps are a lot of things that manufacturers can tweak to change how the process works, or to change how the end material behaves. Generally speaking, the faster a rayon is produced, the less expensive it will be- but it'll also be a lower quality product and the chemical byproducts are harsh/need disposal.

But textile scientists have been working on this issue for a while, and every new iteration of rayon runs better than earlier ones. Chemicals that can be recycled and reused are more expensive, and tweaking stages of the process to make better fabrics adds time to the process. Rayon can definitely be sustainable- it just hasn't been considered popular to make it that way until these last couple decades.

This might all seem extraneous info, but the complexity of it is why it's hard to definitively call an entire class of fabrics 'sustainable' or not. So here is my guide on sustainable rayon purchasing!

-if the garment or fabric bolt shares the brand name of the rayon it is, that's a good sign. You can google the name of it for specifics, but also, if they have a tag advertising the brand of rayon it is, they usually have a blurb on a tag about why the brand is special.

-Anything made under the TENCEL brand is the best stuff on the market re: sustainable practices. Modal and Lyocell are both under the Tencel name. Exactly what you said- these ones operate on a closed loop system where the chemicals and water are re-used for their respective purposes. They also use crops that are fast growing without as much need for water to process.

-Avoid the bargains unless you can verify the source of the rayon. If the base price is excitingly cheap (garment or fabric), the rayon is definitely gonna be low quality.

-Shop from like-minded, small businesses. Fabric shops that have a smaller curated selection are more likely to carry more expensive but higher quality products. If they have spent money on the good stuff, they almost always let you know in the product description.

-if you want rayon but can't get the good stuff, a rayon blended with other natural fibres is a decent compromise from a mitigated harm perspective.

-TO AVOID LIKE THE PLAGUE: Acetate, viscose, bemberg, 'vintage rayon'. The earliest makes of rayon are temperamental to water, heat, and friction (severly so- the earliest makes of rayon would dissolve in water!). They do not stand the test of time, and the older the method, the harsher its manufacturing process.

I'll say one last thing: although sustainable practices ask us to prioritize thrifting and reusing, remember to also consider the investment of your money. While it's ethical to thrift, it's not doing what it's supposed to if you're purchasing things that need frequent replacement. When it counts, buying one thing new that will stay with you for years will be more sustainable than buying x6 of it secondhand over the same span of time.

This got way longer than it needed to be, sorry! Too lazy to edit. Here's some sources:

https://en.m.wikipedia.org/wiki/Rayon

The sources in the wikipedia article are also an excellent place to dig further. Hope this helps!

6 notes

·

View notes

Text

Uncovering the Protective and Green Tints of Vegas Powder Coating

Metalwork has been an artform and an essential fabrication for human needs for millennia. In the modern era, as we become increasingly aware of our environment and the materials that surround us, finding solutions that marry longevity with eco-friendliness is crucial. Powder coating—especially the advanced methods used in bustling hubs like Las Vegas—is one such solution that not only enhances protection but also minimizes environmental impact, ushering in a new wave of eco-conscientious metal fabrication.

Understanding Powder Coating's Framework

Before we glide into the green details, understanding the very framework and working of powder coating is essential. Unlike traditional liquid paints, powder coating doesn't require solvents to keep the binder and fillers in a liquid suspension, making it a 'dry' coating process. This reduction in volatile organic compounds (VOCs) is significant, contributing to cleaner air and less impact on the atmosphere. The powder itself is a blend of resins, pigments, and fillers uniformly mixed and processed into a fine powder.

Durability Balances Environmental Concerns

The durability of powder coating is a remarkable aspect. Once cured, typically through heat, the result is a flexible and long-lasting finish that resists cracking, peeling, and is impervious to chemicals. What this means for metalwork is less frequent recoating, and thus, a minimized environmental footprint. Furthermore, the fact that powder coating can be made to be ultra-thin while maintaining its protective qualities means that less material is needed per coating, again contributing positively to environmental conservation efforts.

The Allure of Vegas Powder Coating's Green Approach

Las Vegas, known for its glitz and glamour, stands out not just for its night skyline but for its steadfast commitment to progressive environmental standards, including in the art of powder coating. Vegas powder coating reflects the city's dedication to sustainable growth. The techniques and materials used by Vegas' powder coaters are often at the forefront of environmental regulations, showcasing that high-stakes quality and environmental responsibility need not be at odds.

The Eco-Friendliness is Clear

The environmental story of powder coating is compelling. With reduced waste due to its electrostatic application process, which ensures that most of the powder adheres to the product, minimal overspray is almost a given. Where there's chairing, it's often recycled, further reducing the environmental burden. The industry's shift towards eco-friendly powders, composed without heavy metals and other harmful additives, is a testament to the commitment of powder coaters towards a sustainable future.

Long-Term Benefits for Consumers and the Earth

Consumers who opt for powder-coated products are not only choosing a durable and high-quality finish but are also making a small yet significant contribution to the preservation of our planet. The resistant nature of powder-coated metals means they last longer, leading to less waste over time. It's a sustainable circle where the benefits to the consumer—finishes that don't fade or require regular maintenance—echo the global benefits in terms of the environment.

Looking to the Horizon

The shift from traditional paint to powder coating is not just an industrial trend; it is a vital step towards a greener future. The example set by Vegas powder coating companies highlights the possibilities of large-scale adoption of sustainable practices in metal fabrication. With innovations in both technologies and materials, the horizon for powder coating appears green and promising.

Powder coating offers a lustrous, durable finish that respects our environment. In a world where green is the new gold, Vegas powder coating exemplifies how functionality and environmental responsibility can converge, making for a future that is bright—in all the right ways.

0 notes

Text

Field Trip to BSU Water Reclamation Facility

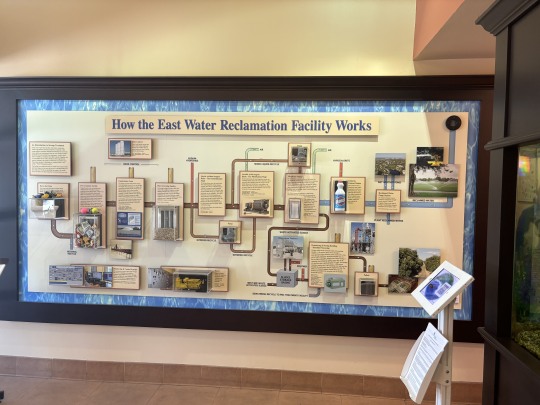

My colloquium class’s field trip to the Bonita Spring Utilities East Water Reclamation Facility introduced us to sewage treatment. As an environmental engineering student, I learned of wastewater treatment and previously visited this site. It was a great experience getting a refresher of the subject and of the good this facility does in mitigating the amount of debris heading to landfills. The facility sells the reclaimed water, the result of all the treatment, as irrigation water and sells the dried pellets, the end product of the solid waste material, as fertilizer by the ton. To get to this point, the water goes through multiple intensive steps to remove the pollution that makes people sick. This can be seen in Photograph 1 below:

Robertson wrote that “Toxins that are water-soluble move through the environment easily because water is everywhere on this water planet” (Robertson, 2021, p. 171). “Hydrogen oxide, commonly known as water, is the universal solvent. One of its most significant chemical properties is its ability to dissolve other substances, which makes it easily contaminated, allowing it to dissolve and carry pollutants for long distances. Once water is polluted it is difficult, and thus expensive, to restore” (Robertson, 2021, p. 177).

The most critical part of the process is the removal of the pollutants. It is pricey, difficult, and required under federal and state laws in order to meet certain expectations that become stricter and harder to keep up with for older facilities. As more attention falls on endocrine disruptors and the forever chemical PFAs, more concern grows on how to treat them. As of now there are no requirements for water and wastewater treatment plants to treat the water to remove these newer challenges. That doesn’t stop the BSU Facility from worrying about it, but they also worry about more. With the increase of population and fluctuations from snowbirds, they are challenged with processing all the water coming through at the peak of season. This can cause the facility to handle 16 million gallons per day according to the handout provided by the BSU facility.

The facility has won plenty of awards and gained attention for their work in the Florida Water Resources Journal. They’ve worked through hurricanes, peak season, when things break, and continue to make things better. The recycling of the sewage water has allowed this facility to make money for the city of Bonita Springs. This method can be related to the cradle-to-cradle method. “Cradle to cradle design is an example of an approach to the industrial economy known as the circular economy. The circular-economy concept is modeled on nature, where waste from one process becomes good for another, often summarized “waste equals food”” (Robertson, 2021, p. 343-344) To me, this design reflects the system that BSU facility has going on in many ways. Of course the obvious thing is that some waste does end up in the landfill, or follows the cradle-to-grave design, but plenty is recycled. The reclaimed water (Photograph 2) sold can be used to water lands with the dried pellets (Photograph 3) used as fertilizer. This food can be grown and eaten by the people nearby, which will result in their waste entering the wastewater treatment facility. This would complete the cradle-to-cradle design that is supposed to find no end.

Photograph 2: Reclaimed water from the BSU Facility

Photograph 3: Scott, BSU worker, with dried pellets that the facility sells

References:

Bonita Springs Utilities East Water Reclamation Facility. "How this facility works" [Handout].

Rende, Samantha. (2024). Photograph 1 [Photograph].

Rende, Samantha. (2024). Photograph 2 [Photograph].

Rende, Samantha. (2024). Photograph 3 [Photograph].

Robertson, Margaret. Sustainability Principles and Practice, Taylor & Francis Group, 2021. ProQuest Ebook Central, https://ebookcentral.proquest.com/lib/fgcu/detail.action?docID=6457832.

#colloquium#sustainability#bonita springs#wastewatertreatment#wastewatermanagement#reclaimed water#Cradle-to-cradle

0 notes

Text

Eco-Chic: How Sustainable Materials Are Shaping Men's Fashion Trends

When it comes to men's fashion, sustainability is no longer just a passing trend; it's a movement that is shaping the industry's future. As the world becomes increasingly aware of the environmental impact of fast fashion, men's fashion brands are embracing eco-friendly practices and materials. From organic cotton and recycled fabrics to innovative fibers created from renewable resources, sustainable materials are redefining men's fashion aesthetics, offering a new kind of style that blends ethics with elegance. Let's explore how these materials are transforming men's fashion and influencing the choices of fashion-forward individuals.

Organic Cotton: The Soft Side of Sustainability

Organic cotton is one of the most widely recognized sustainable materials in men's fashion. Grown without the use of synthetic chemicals and pesticides, organic cotton reduces the harmful impact on both the environment and the workers involved in its cultivation. The use of organic cotton in men's clothing brings a soft, breathable, and gentle touch to garments, while also promoting safer working conditions and soil conservation.

Recycled Fabrics: Giving New Life to Fashion

Recycled fabrics are gaining momentum in men's fashion as brands find innovative ways to repurpose materials like plastic bottles, old garments, and discarded textiles. These fabrics undergo a meticulous process of washing, shredding, and transforming the waste into new fibers, which are then woven into new fabrics. By embracing recycled fabrics, men's fashion brands are diverting waste from landfills and reducing the need for new raw materials, offering environmentally responsible alternatives without compromising style or quality.

Hemp: Cultivating Sustainable Style

Hemp, a durable and versatile plant, is making a comeback in men's fashion due to its environmentally friendly properties. Compared to other crops, hemp requires less water, pesticides, and synthetic fertilizers to grow, making it a more sustainable choice. Hemp fibers are lightweight, breathable, and possess excellent moisture-wicking properties, making them ideal for warm-weather clothing. From shirts and trousers to accessories like belts and bags, hemp is elevating men's fashion with its natural charm.

Tencel: The Eco-Friendly Wonder Fiber

Tencel, also known as lyocell, is a fabric derived from sustainably harvested wood pulp, most commonly from eucalyptus trees. Its production process involves a closed-loop system that recycles water and solvents, minimizing waste and energy consumption. Tencel is prized for its silky-smooth texture, breathability, and moisture-wicking properties that keep the wearer cool and comfortable. It has gained popularity in men's fashion for its versatility, featuring in everything from shirts and pants to suits and outerwear.

Bamboo: The Sustainable Wonder Grass

Bamboo is an incredibly versatile and sustainable material that is finding its way into men's fashion. It is a fast-growing grass that requires minimal water and no pesticides for cultivation, making it highly renewable and environmentally friendly. Bamboo fibers are soft, breathable, and naturally antimicrobial, offering excellent comfort and hygiene for men's clothing. From bamboo socks and underwear to shirts and even tailored suits, bamboo is redefining eco-chic style.

In conclusion, sustainable materials are quietly revolutionizing men's fashion, offering stylish alternatives that prioritize environmental responsibility without compromising on quality or design. With organic cotton, recycled fabrics, hemp, Tencel, bamboo, and other sustainable materials reshaping the industry, men's fashion is embracing a new era of eco-chic style. Mens clothing sale events featuring these sustainable materials present a great opportunity to update your wardrobe while supporting eco-friendly fashion. By choosing garments made from these materials, fashion-forward individuals can make a positive impact on the planet while looking stylish and sophisticated.

youtube

0 notes

Text

Expert Insights: How to Extend the Lifespan of Your Suits through Dry Cleaning

In the bustling city of Kolkata, where style meets tradition, maintaining the impeccable appearance of suits is essential for both personal and professional endeavours. However, amidst the humidity and urban challenges, preserving the longevity of these garments demands strategic care. Suit dry cleaning Kolkata emerges as a crucial practice, offering not just cleanliness but also extending the lifespan of these cherished ensembles. This comprehensive guide delves into the nuances of suit dry cleaning in Kolkata, unravelling insights on how this process safeguards and enhances the durability of your suits.

Understanding the Significance of Dry Cleaning:

Dry cleaning in Kolkata serves as the cornerstone of maintaining the pristine condition of suits. Unlike traditional washing methods, dry cleaning utilizes solvent-based solutions to remove stains and dirt without saturating the fabric with water. This gentle yet effective approach ensures that delicate materials, intricate designs, and tailored fits remain intact, preventing damage and distortion.

Preserving Fabric Integrity:

The fabric of a suit is its essence, reflecting craftsmanship and quality. Suit dry cleaning Kolkata prioritizes fabric integrity, employing specialized techniques that cater to diverse materials such as wool, silk, linen, and blends. By entrusting your suits to experienced professionals versed in dry cleaning Kolkata, you safeguard against shrinkage, colour fading, and fabric weakening, thus preserving their original texture, sheen, and drape.

Combatting Stains and Odours:

In Kolkata's dynamic lifestyle, encounters with stains and odours are inevitable. Whether it's from daily wear, culinary indulgences, or environmental factors, these blemishes can mar the aesthetic appeal of suits if not addressed promptly. Suit dry cleaning Kolkata offers a reliable solution, utilizing advanced stain removal treatments tailored to the specific nature of stains, ensuring comprehensive eradication without compromising fabric integrity.

Enhancing Longevity and Appearance:

Beyond mere cleanliness, dry cleaning in Kolkata enhances the longevity and appearance of suits, prolonging their lifespan for years to come. The meticulous process eliminates accumulated dirt, oils, and pollutants embedded in the fabric, preventing deterioration and discoloration. Moreover, professional dry cleaning rejuvenates the vibrancy of colours and restores the crispness of lines, revitalizing the overall aesthetic appeal of suits.

Protecting Against Wear and Tear:

Regular wear exposes suits to friction, creasing, and structural strain, gradually diminishing their pristine condition. Suit dry cleaning in Kolkata acts as a shield against wear and tear, mitigating the adverse effects of daily use. Through specialized cleaning methods and expert handling, dry cleaning professionals alleviate stress points, reinforce seams, and maintain the garment's structural integrity, ensuring that suits retain their original form and resilience.

Preserving Tailored Fits:

One of the defining features of a well-crafted suit is its tailored fit, sculpted to accentuate the wearer's physique and exude sophistication. However, improper cleaning techniques can compromise this meticulous tailoring, resulting in misshapen silhouettes and disproportionate proportions. Suit dry cleaning in Kolkata prioritizes the preservation of tailored fits, employing methods that respect the garment's construction while effectively cleansing and rejuvenating its appearance.

Mitigating Environmental Impact:

In today's eco-conscious era, sustainability is paramount in every aspect of life, including garment care. Suit dry cleaning in Kolkata embraces eco-friendly practices that minimize environmental impact without compromising cleaning efficacy. From solvent recycling to energy-efficient technologies, dry cleaning establishments in Kolkata prioritize sustainability, ensuring that your commitment to style aligns with environmental stewardship.

Professional Expertise and Attention to Detail:

Central to the success of suit dry cleaning in Kolkata is the proficiency and dedication of its practitioners. With a wealth of experience and meticulous attention to detail, dry cleaning professionals in Kolkata possess the expertise to address diverse cleaning challenges and garment intricacies. Whether it's delicate embellishments, intricate patterns, or tailored linings, these experts navigate complexities with precision, delivering impeccable results that exceed expectations.

Investing in Convenience and Confidence:

In the fast-paced urban landscape of Kolkata, convenience is a prized commodity. Suit dry cleaning services in Kolkata offer a convenient solution for busy individuals, streamlining the process of garment care without compromising quality. By entrusting your suits to reputable dry cleaning establishments, you not only save time and effort but also gain peace of mind, knowing that your prized ensembles are in capable hands.

Conclusion:

In the vibrant tapestry of Kolkata's sartorial culture, the longevity of suits hinges upon strategic care and meticulous attention to detail. Suit dry cleaning in Kolkata emerges as a cornerstone of garment maintenance, offering a blend of tradition, expertise, and innovation to preserve the pristine condition of these cherished ensembles. By embracing the insights and practices outlined in this guide, you can embark on a journey of style and longevity, ensuring that your suits remain timeless symbols of elegance and refinement for years to come.

0 notes

Text

Find out how to save water and maximize your yield with a comprehensive guide on water-saving hydroponic systems. Get the insights you need to become an expert!

Table of ContentsWater-Saving Hydroponic Systems: A Comprehensive GuideIntroduction to HydroponicsWhat is Hydroponics?The Importance of Water Conservation in HydroponicsTypes of Water-Saving Hydroponic SystemsNutrient Film Technique (NFT)AeroponicsDrip SystemsBenefits of Water-Saving Hydroponic SystemsEfficient Water UseIncreased Crop YieldSpace OptimizationSetting Up a Water-Saving Hydroponic SystemChoosing the Right SystemEssential ComponentsMaintenance TipsConclusionFrequently Asked Questions

Water-Saving Hydroponic Systems: A Comprehensive Guide

Discover the world of hydroponic gardening and how you can save water with a complete guide to water-saving hydroponic systems. Learn all the ins and outs now!

Introduction to Hydroponics

What is Hydroponics?

Hydroponics is a method of growing plants without soil, using mineral nutrient solutions in a water solvent. This technique allows plants to receive their necessary nutrients directly from the water, eliminating the need for soil and resulting in faster growth and higher yields. It's a revolutionary approach to agriculture that has gained popularity due to its efficiency and sustainability. Hydroponics can be used to grow a wide variety of plants, including vegetables, fruits, and flowers. It's particularly useful in urban environments where space is limited and soil quality is poor.

The Importance of Water Conservation in Hydroponics

In traditional farming, a significant amount of water is wasted due to evaporation, runoff, and inefficient application. Hydroponics, on the other hand, uses a closed system where water can be recycled, leading to a significant reduction in water usage. This is particularly important in areas where water is scarce or expensive. By using hydroponics, farmers can save up to 90% of the water used in traditional farming methods. This not only conserves a valuable resource but also reduces the cost of farming, making it a more sustainable and economical option.

Types of Water-Saving Hydroponic Systems

Nutrient Film Technique (NFT)

NFT is a type of hydroponic system where a thin film of nutrient-rich water is recirculated over the roots of the plants, which are supported by a slight tilt. This system is highly water-efficient as it recycles the nutrient solution. The constant circulation of water ensures that the plants receive a steady supply of nutrients, while the slight tilt allows excess water to drain back into the reservoir. This system can save up to 95% of water compared to traditional farming methods.

Aeroponics

In aeroponics, plants are grown in an air or mist environment without the use of soil or an aggregate medium. Water and nutrients are delivered to the plants via a fine mist, which reduces water usage significantly. The mist provides the plants with a perfect balance of nutrients and oxygen, promoting healthy growth. Aeroponics is considered the most water-efficient hydroponic system, with potential water savings of up to 98%.

Drip Systems

Drip systems deliver water and nutrients directly to the root zone of each plant, which reduces waste and increases water efficiency. The system can be set up to recirculate unused water, further enhancing its water-saving capabilities. Drip systems are highly customizable and can be adjusted to meet the specific needs of each plant. They can save up to 60% of water compared to traditional irrigation methods.

Benefits of Water-Saving Hydroponic Systems

Efficient Water Use

Water-saving hydroponic systems use up to 90% less water than traditional farming methods. The closed-loop systems recycle water, reducing waste and making them ideal for areas with limited water resources. Over a period of one year, a hydroponic farm can save millions of gallons of water compared to a traditional farm of the same size.

Over 1 year, a small hydroponic farm can save over 1 million gallons of water.

Over 5 years, the savings can amount to over 5 million gallons of water.

Increased Crop Yield

Hydroponic systems often produce higher yields than traditional farming methods. This is because the plants receive exactly what they need when they need it, reducing stress and promoting healthy, rapid growth. Studies have shownthat hydroponic systems can produce up to 3 times the yield of traditional farming methods.

A study found that hydroponic lettuce grew 3 times faster than soil-grown lettuce.

Another study found that hydroponic tomatoes produced double the yield of soil-grown tomatoes.

Space Optimization

Hydroponic systems can be set up in a variety of spaces, from large greenhouses to small indoor areas. This makes it possible to grow food in urban environments, rooftops, and other spaces where traditional farming is not feasible. With vertical hydroponic systems, you can grow up to 10 times the amount of crops in the same space as traditional farming.

A vertical hydroponic farm can produce up to 10 times the yield of a traditional farm in the same space.

Urban farmers have successfully set up hydroponic systems in basements, rooftops, and even old warehouses.

Setting Up a Water-Saving Hydroponic System

Discover the best water-saving hydroponic systems for your home or commercial garden.

Choosing the Right System

The type of hydroponic system you choose will depend on your specific needs, including the type of plants you wish to grow, the space you have available, and your budget. Research the different types of systems and consider consulting with a hydroponics expert to make an informed decision. Each system has its own advantages and disadvantages, so it's important to choose the one that best fits your needs.

Essential Components

Regardless of the type of hydroponic system you choose, there are several essential components you will need. These include a reservoir for holding the nutrient solution, a pump to circulate the water, a growing medium for the plants, and a system for delivering the nutrients to the plants. You'll also need a way to support the plants, such as a trellis or netting, and a light source if you're growing indoors.

Maintenance Tips

Maintaining a hydroponic system involves regularly checking and adjusting the pH and nutrient levels, cleaning the system to prevent the buildup of algae and other contaminants, and monitoring the plants for signs of disease or nutrient deficiencies. Regular maintenance will ensure that your system continues to operate efficiently and that your plants remain healthy.

Conclusion

Water-saving hydroponic systems offer a sustainable and efficient way to grow plants, making them an excellent choice for both commercial growers and home gardeners. By understanding the different types of systems and how they work, you can choose the best system for your needs and start enjoying the benefits of hydroponics.

Frequently Asked Questions

What is the most water-efficient hydroponic system?

Aeroponics is considered the most water-efficient hydroponic system as it uses a mist to deliver nutrients, minimizing water usage.

Can any plant be grown hydroponically?

While most plants can be grown hydroponically, some are better suited to the method than others. Leafy greens, herbs, and tomatoes are commonly grown using hydroponics.

How often should I check my hydroponic system?

It's recommended to check your hydroponic system daily for pH and nutrient levels, and to monitor plant health.

Is hydroponic farming organic?

Hydroponic farming can be organic if it uses organic nutrient solutions and avoids synthetic pesticides and herbicides.

Can hydroponic systems be used outdoors?

Yes, hydroponic systems can be used outdoors, but they may require additional protection from weather and pests.

Hesi PowerClean: This is a cleaning agent specifically designed for hydroponic systems.

It's environmentally friendly and helps to keep your system running smoothly.

Hesi Boost: This is another product from Hesi that's designed to boost the performance of your hydroponic system. It's eco-friendly and helps to enhance plant growth.

220V Electric Sprayer High Pressure Pesticide Sprayer Garden Disinfection Equipment: This high-pressure sprayer can be used for disinfecting your hydroponic system. It's energy-efficient and designed to minimize water usage.

0 notes

Text

Smart textiles offer many potential wearable technology applications, from therapeutics to sensing to communication. For such intelligent textiles to function effectively, they need to be strong, stretchable, and electrically conductive. However, fabricating fibres that possess these three properties is challenging and requires complex conditions and systems.

Drawing inspiration from how spiders spin silk to make webs, a team of researchers led by Assistant Professor Swee-Ching Tan from the Department of Materials Science and Engineering under the National University of Singapore's College of Design and Engineering, together with their international collaborators, have developed an innovative method of producing soft fibres that possess these three key properties, and at the same time can be easily reused to produce new fibres. The fabrication process can be carried out at room temperature and pressure, and uses less solvent as well as less energy, making it an attractive option for producing functional soft fibres for various smart applications.

Read more.

#Materials Science#Science#Textiles#Smart materials#Wearable technology#Fibers#Spiders#Biomimicry#Spider silk#National University of Singapore

28 notes

·

View notes

Text

HDPE Pipe Grade Granules: Modern Solutions for Pipe Manufacturing

High-Density Polyethylene (HDPE) granules are revolutionizing the pipe manufacturing industry. These versatile plastic pellets offer a unique combination of properties that make them ideal for a wide range of piping applications. In this article, we’ll explore the advantages of HDPE granules and how they are shaping the future of pipe manufacturing.

HDPE Pipe Grade Granules

Why Choose HDPE Granules?

Several key characteristics make HDPE granules the preferred choice for modern pipe production:

· Superior Strength and Durability: HDPE boasts exceptional strength-to-weight ratio, making it highly resistant to impact, pressure, and external stressors.

· Enhanced Flexibility: HDPE pipes can bend without breaking, allowing for greater adaptability during installation and accommodating ground movement.

· Excellent Chemical Resistance: HDPE is impervious to a wide range of chemicals, making it suitable for transporting various liquids and gases without degradation.

· Corrosion-Resistant: Unlike metal pipes, HDPE is immune to corrosion, ensuring long-lasting performance and minimal maintenance needs.

· Lightweight Design: HDPE pipes are significantly lighter than traditional metal alternatives, simplifying transportation, handling, and installation.

· Cost-Effective: HDPE offers a cost-competitive solution compared to metal pipes, with lower material and installation expenses.

· Easy Installation: HDPE pipes can be joined using various techniques like heat fusion or solvent cementing, making for a quick and efficient installation process.

· Extended Lifespan: HDPE pipes boast a long lifespan, often exceeding 50 years, minimizing replacement costs and maintenance downtime.

· Environmentally Friendly: HDPE is recyclable, making it a sustainable choice for environmentally conscious projects.

HDPE Pipe Grade Granules

Modern Applications of HDPE Granules

HDPE granules are used in a vast array of pipe manufacturing applications, including:

· Potable Water Distribution: HDPE’s superior hygiene and chemical resistance make it ideal for transporting drinking water.

· Wastewater Collection: HDPE’s durability and corrosion resistance ensure safe and efficient transportation of wastewater.

· Irrigation Systems: HDPE’s lightweight design and flexibility make it perfect for agricultural irrigation systems.

· Industrial Piping: HDPE pipes are widely used in various industrial applications due to their high strength and chemical resistance.

· Gas Distribution: HDPE can safely transport natural gas and other gaseous materials due to its excellent pressure capacity.

· Marine Applications: HDPE’s resistance to corrosion and saltwater makes it suitable for offshore pipelines and marine infrastructure.

HDPE Pipe Grade Granules

The Future of Pipe Manufacturing

The use of HDPE granules is expected to continue growing in the pipe manufacturing industry due to its numerous advantages. As technology advances, we can expect even more innovative applications for HDPE pipes, further enhancing their efficiency, sustainability, and cost-effectiveness.

#HDPE pipes#plastic pipes#pipe manufacturing#pipe installation#bulkbuying#bulkmaterials#industrialsupplies#sellerbenefits#reliablesourcing#qualityassured#industrialmaterials#b2binnovation#viztaar

0 notes

Text

Adhesion Innovation: How Solvent-Based Adhesives Enhance Performance and Durability in 2024

Solvent-based adhesives have long been the backbone of various industries, offering unparalleled bonding strength, versatility, and reliability in a wide range of applications. From automotive assembly and construction to packaging and electronics, solvent-based adhesives play a crucial role in joining diverse materials and components, ensuring structural integrity, and enhancing product performance. As we enter 2024, the Solvent-based Adhesives Market continues to thrive, driven by factors such as the demand for high-performance bonding solutions, technological advancements, and expanding applications across industries. This article delves into the key trends, market dynamics, and factors shaping the Solvent-based Adhesives Market in the coming years.

Market Overview:

The Solvent-based Adhesives Market is experiencing steady growth, with a projected Compound Annual Growth Rate (CAGR) exceeding 4% from 2022 to 2024. This growth is fueled by factors such as the wide-ranging applications of solvent-based adhesives in manufacturing processes, the robust demand from end-user industries, and ongoing innovations in adhesive formulations and technologies.

Key Factors Driving Growth:

Versatility and Performance Excellence: Solvent-based adhesives offer exceptional bonding strength, durability, and resistance to harsh environmental conditions, making them suitable for a diverse range of applications. From bonding metals, plastics, and composites to sealing joints and laminating materials, solvent-based adhesives provide reliable and long-lasting adhesion solutions across industries.

Expansion of End-User Industries: The Solvent-based Adhesives Market benefits from the growth of key end-user industries such as automotive, construction, packaging, and electronics. In automotive assembly, solvent-based adhesives are used for bonding components, sealing seams, and enhancing vehicle durability and safety. Similarly, in the construction sector, these adhesives are employed for structural bonding, flooring installation, and insulation applications.

Technological Advancements and Product Innovations: Ongoing research and development efforts focus on enhancing the performance, efficiency, and sustainability of solvent-based adhesives. Innovations in adhesive formulations, curing mechanisms, and application techniques enable manufacturers to address evolving customer needs, comply with regulatory requirements, and improve process efficiency in various industrial applications.

Demand for Sustainable Adhesive Solutions: Sustainability considerations drive the demand for solvent-based adhesives with reduced volatile organic compound (VOC) emissions and environmental impact. Adhesive manufacturers invest in developing eco-friendly formulations, incorporating bio-based raw materials, and adopting solvent recovery and recycling technologies to minimize their carbon footprint and meet sustainability goals.

Challenges and Opportunities:

While the Solvent-based Adhesives Market presents significant growth opportunities, challenges such as regulatory restrictions on solvent emissions, volatile raw material prices, and competition from alternative adhesive technologies remain. However, these challenges also create opportunities for industry players to innovate, invest in research and development, and diversify product portfolios to address emerging market trends and customer preferences.

For More Info@ https://www.gmiresearch.com/report/solvent-based-adhesives-market/

Conclusion:

In 2024, the Solvent-based Adhesives Market stands as a cornerstone of industrial bonding solutions, enabling manufacturers to achieve superior product performance, reliability, and durability across diverse applications. As industries continue to evolve and demand high-performance adhesive solutions, the market's growth is not just about adhesives; it is about enabling innovation, efficiency, and sustainability in manufacturing processes. The Solvent-based Adhesives Market is not merely a segment of the chemical industry; it is a critical enabler of product innovation and industrial progress. In embracing the opportunities presented by technological advancements, market demand, and sustainability imperatives, the Solvent-based Adhesives Market is not just bonding materials; it is shaping the future of manufacturing, driving excellence and reliability in industrial applications for years to come.

0 notes

Text

Turning Hazards into Assets: Benzoil's Expertise in Waste-to-Product Transformation

In the realm of waste management, Benzoil stands as a beacon of innovation, specialising in waste oil disposal, recycling, collection, and removal services. As a dedicated player in Australia's environmental landscape, Benzoil is committed to transforming hazards into valuable assets through its expertise in waste-to-product solutions.

Unveiling Benzoil's Mission

A Network of Sustainability

Benzoil, a prominent waste and resource recovery name, navigates industry challenges with a deeply connected network and strategic partnerships. This foundation enables us to uncover best practices for waste and surplus material, setting the stage for sustainable outcomes.

Waste-to-Product Pioneers

At Benzoil, we view waste as an opportunity, not a burden. Our mission revolves around the utilisation of industrial waste as a resource. With a profound understanding of technical, commercial, and environmental drivers, we offer comprehensive recovery, transformation, and disposal solutions.

Oil and Gas Management

Recovering Used Oil's Value

Many spent materials can be fully recovered, including electrical insulating fluids (transformer oil), hydraulic oil, garage or workshop oil, lubricants, turbine and gearbox oil, and synthetic oil. Benzoil actively procures and markets a select range of hydrocarbon products, emphasising the inherent value of used oil.

Beyond Oil: Solvents and Ethylene Glycol

In addition to oil, Benzoil undertakes large-scale projects in the recovery of solvents and ethylene glycol, showcasing our commitment to diverse waste-to-product transformations.

Waste-to-Product Transformation

Unlocking Potential in Industrial Waste

Benzoil actively pursues industrial waste materials with untapped potential. Our vast experience and connections empower us to transform waste materials and process by-products into value-added products. Successful transformations include turning sludge into organic-based fertilisers, clays and sawdust into cat litter, fuel pellets from petroleum coke dust, and recovering valuable metals from spent batteries.

Hazardous Waste Processing & Disposal

Compliant and Sustainable Solutions

Benzoil leverages compliant and industry best practice waste disposal partners when beneficial re-use is not feasible or destruction is required. We handle liquid, solid, contained gas, or sludge wastes with dangerous or potentially harmful properties, ensuring responsible and environmentally friendly disposal.

Versatility in Waste Streams

Benzoil is geared to work with a variety of waste streams, including chemical by-products from industrial processes, legacy materials and waste stockpiles, surplus or out-of-spec products, and projects involving decontamination, decommissioning, and demolition.

Conclusion

In the journey from hazards to assets, Benzoil emerges as a reliable partner in waste-to-product transformations. Our commitment to sustainability, coupled with a keen understanding of waste management intricacies, positions us as leaders in the industry.

FAQs

How does Benzoil handle hazardous waste disposal in Sydney?

Benzoil utilises compliant partners for industry best practice in hazardous waste disposal, ensuring safe and environmentally friendly solutions.

What types of oil does Benzoil actively seek for recovery?

Benzoil actively seeks used oils, including transformer oil, hydraulic oil, garage or workshop oil, lubricants, turbine and gearbox oil, and synthetic oil.

Can Benzoil handle large-scale waste-to-product transformations?

Yes, Benzoil specialises in large-scale projects, transforming various industrial waste materials into value-added products.

What are some successful waste transformations by Benzoil?

Benzoil has successfully transformed sludges into organic-based fertilisers, clays and sawdust into cat litter, fuel pellets from petroleum coke dust, and recovered valuable metals from spent batteries.

How does Benzoil ensure compliance in hazardous waste processing?

Benzoil ensures compliance through strategic partnerships with industry best practice waste disposal partners, adhering to regulations for responsible waste processing.

0 notes

Text

Everything you need to know about stainless steel pipes

Stainless steel pipes are employed in the piping systems to transport gas and fluid. Steel pipes are manufactured from a steel alloy that includes nickel and chromium, giving corrosion-resistance capacity to stainless steel. This pipe variant can excellently resist oxidation, which makes it a low-maintenance solution suitable for high chemical applications as well as temperature.

But, the money you invest will be worth you in the long run. Stainless steel pipes go through an extrusion or welding process. They offer high corrosion resistance and long-lasting durability.

Common industries where stainless steel pipes are employed

Check the Price list SS 304 fittings to know the rate tags of the latest SS pipes and fittings. Come, let’s see the major areas where SS pipes are used:

Textile operations

Food processing

Breweries

Oil and gas transportation

Water treatment projects

Chemical applications

Fertilizers and pesticides

Construction

Automotive components

Pharmaceuticals

Check Price List Duplex Plates to see the range of sizes that stainless steel pipes are available to meet your needs. Check also the pipe schedule chart to decide on the pipe schedule value using the wall thickness and OD of the pipe.

How 304 stainless steel version differ from the 316 version?

300 series grade SS variants are made with a combination of chromium and nickel alloy. These are manufactured to make a wide range of stainless steel products. These two variants are highly durable to maintain strength at high temperatures, capable of resisting corrosion, and easy to maintain. Choosing a material for pipes is fully dependent on how you will use the end product and the ambiance where the pipe is going to be installed. Check Price list SS 304 pipe to know the price variations in stainless steel products available in the market.

304 stainless steel variant seems to be the most common material employed widely as it is easy to sanitize and corrosion resistant as well. This model is generally used for food and beverage industries or in building applications. Though the 316 variant is corrosion-resistant and easy to clean, it is more resistant to corrosion from solvents and chemicals. Thus, the 316 model is more preferred for surgical and industrial applications or marine and outdoor applications because of its high capacity to resist chloride corrosion.

What are the benefits stainless steel pipes offer to your applications?

Check Price List Carbon Steel Fittings to see the difference from stainless steel pipes. Stainless steel pipes come with a lot of advantages, such as:

Highly durable

Lightweight

Long-lasting

Easy to install

High flow rates

Scratch resistant

Easy to sanitize

Super corrosion-resistance capacity

Environment friendly

Fully recyclable

Hence check Price of Carbon Steel Flanges as well as stainless steel flanges and you will understand why the stainless steel variant is preferred.

0 notes

Text

Revolutionizing Resource Renewal: Scaling up Sustainable Recycling for Critical Materials - Technology Org

New Post has been published on https://thedigitalinsider.com/revolutionizing-resource-renewal-scaling-up-sustainable-recycling-for-critical-materials-technology-org/

Revolutionizing Resource Renewal: Scaling up Sustainable Recycling for Critical Materials - Technology Org

A critical-materials recycling technique pioneered at Oak Ridge National Laboratory by researchers in the Department of Energy’s Critical Materials Innovation Hub, or CMI, recently earned special recognition from the journal Advanced Engineering Materials, and the associated research project received a new phase of funding for research and development.

From left, researchers Syed Islam and Ramesh Bhave discuss the nickel sulfate recovered from end-of-life lithium-ion batteries using the membrane solvent extraction process they co-invented at ORNL. Credit: Carlos Jones/ORNL, U.S. Dept. of Energy

The journal selected a paper about the technology for its collection of the most outstanding articles published throughout the past year. The article, featured on the journal’s front cover, explains how the researchers applied the team’s membrane solvent extraction, or MSX, method to recover, separate and purify rare earth elements, or rare earths, from scrap permanent magnets taken from electronic waste.

Permanent magnets, which retain magnetic properties even in the absence of an inducing field or current, are used extensively in clean energy and defense applications. Rare earths are challenging to access because they are scattered across Earth’s crust, yet they are key components in many modern technologies. Recycled rare earths can be used to make new permanent magnets, accelerate chemical reactions and improve the properties of metals when included as alloy components.

“The editors chose the paper because it demonstrated the scalability and secure, long-term performance of the process,” said ORNL scientist Syed Islam, who co-invented the recycling approach and led the collaborative scale-up efforts. “Our industrial partner Momentum Technologies performed a technoeconomic analysis of all the inputs, extracting chemicals, membranes and lifetimes of the materials. Additionally, they validated that the process recovered more than 95% of the rare earth product at greater than 99.5% purity.”

ORNL’s Ramesh Bhave, the project’s principal investigator since it began in 2013 and a co-inventor of the technology, commented on the article’s exceptional thoroughness. “It discusses a full range of aspects of the process along with the results, so the reader gets a complete story,” he said. “We had enough information from this research for many papers but wanted to ensure the integrated process was provided so the reader could see how it is applicable to a large number of materials for recycling.”

Efficient, versatile recycling

The process uses modules composed of polymer hollow fiber membranes that are inexpensive and commercially available.

In the first step of the process, scrap magnets are crushed and dissolved in a mineral acid. The resulting solution is then continuously fed into the membranes where the rare earths are selectively removed by the extractant and form a so-called complex.

The complex passes through the membrane and meets with a solution that isolates the rare earths to form a rich solution that is converted to rare earth oxide powders, which are suitable for a wide range of industrial applications. Iron, a non-rare earth, is collected separately as a co-product.

“Compared with alternatives such as hydro-metallurgy-based solvent extraction, our MSX method uses fewer chemicals and costs 100 times less,” Bhave said. “The technique is advantageous for other reasons as well: It is scalable and works at low temperatures and low pressure. It recycles acid and water and generates minimal waste to promote a circular economy. MSX requires low capital and operating costs. Moreover, it is robust and versatile, with the ability to process a wide range of complex feedstocks.” Feedstocks are the raw input materials for the recycling process.

Pure recovery, seamless repurposing

Bhave said that MSX can recover and recycle high-purity cathode-active materials to meet the manufacturers’ specific requirements for the creation of new products. Cathode-active materials are a crucial part of a lithium-ion battery’s structure, responsible for the flow of electric current and energy storage.

The researchers have demonstrated that by adjusting the chemistry and adding stages to their technique, they can individually separate and recover cobalt, nickel and lithium from battery waste.

To supply the project with the necessary raw materials, Momentum Technologies takes lithium-ion batteries from end-of-life items, such as electric vehicle systems and cell phones, and crushes them together to create a powder, called black mass, which is fed into the recycling process. The individual critical elements — cobalt, nickel and lithium — are removed from the black mass in stages.

“The greater-than-99% pure material resulting from the process can be combined to make new lithium-ion batteries with our industry partner,” Islam said. “Again, as was the case with rare earths recovery, a major advantage of our approach is scalability. For example, should the demand for the recycling of battery metals for a particular product suddenly grow, the number of membrane modules can be increased for a greater volume of output.”

Boosting capabilities, collaborations

The critical materials recovery project has spanned two, five-year phases of CMI funding. In October, CMI’s funding was extended for another five years, which will allow the project to continue with a renewed focus. The endeavor will now aim to develop and advance the separation of heavy rare earths from light rare earths and generate intellectual property and patents for new technologies.

The two groups of rare earths have distinct properties and applications that play a crucial role in the respective industrial significance and economic value. Momentum Technologies has licensed the team’s technology for removing heavy rare earths from light rare earths. Additionally, the CMI funding supports the team studying the use of their method on materials extracted during mining operations.

Caldera Holding LLC, the owner and developer of the Pea Ridge Mine in Missouri, has entered a nonexclusive research and development licensing agreement with ORNL to apply the MSX approach to separate rare earths from mixed mineral ores. The Pea Ridge Mine is fully permitted and has significant levels of terbium, dysprosium, holmium and other heavy rare earths that are critical for various technological and industrial applications, including electric vehicle motors and advanced defense systems for U.S. national security.

Additionally, a collection of six technologies developed by ORNL scientists has been licensed to a company focused on extracting lithium from wastewater produced by oil and gas drilling.

Lithium-ion batteries power electric vehicles, consumer electronics and defense technologies, and they provide energy storage for the nation’s power grid. Developing domestic sources for lithium, both raw and refined, is critically important to the U.S. economy. The worldwide lithium-ion battery market is projected to grow by a factor of 5 to 10 in the next decade.

ORNL is also exploring a strategic partnership project with Cirba Solutions. Cirba Solutions was awarded grants of $75 million and $10 million from the Bipartisan Infrastructure Law to expand and upgrade its lithium-ion recycling facility in Lancaster, Ohio.

Furthermore, partnering with ORNL and Momentum Technologies, the critical materials research team plans to apply the Bipartisan Infrastructure Law funding to provide recovered lithium-ion battery materials for Cirba Solutions and ORNL’s Electrification and Energy Infrastructures Division.

The technologies from this research also hold promise for helping to build the nation’s stockpile of critical materials for aerospace and defense applications.

Vital support, effective partnerships

The MSX research and development was supported by the Technology Commercialization Fund, DOE’s Advanced Materials and Manufacturing Technologies Office, or AMMTO, and the industrial licensee Momentum Technologies, Inc. AMMTO, part of the Office of Energy Efficiency and Renewable Energy, funded this foundational research through CMI.

CMI seeks to accelerate innovative scientific and technological solutions to develop resilient and secure supply chains for rare earth metals and other materials critical to the success of clean energy technologies. ORNL has contributed strategic direction to those efforts since CMI began in 2013. This contribution includes providing leaders for focus areas and projects that developed new innovations in aluminum-cerium alloys and magnet recycling.

UT-Battelle manages ORNL for DOE’s Office of Science. The single largest supporter of basic research in the physical sciences in the United States, the Office of Science is working to address some of the most pressing challenges of our time. For more information, visit https://energy.gov/science.

Source: Oak Ridge National Laboratory

You can offer your link to a page which is relevant to the topic of this post.

#advanced materials#aerospace#alloys#aluminum#Analysis#applications#approach#Article#Articles#batteries#battery#cell#chemical#chemical reactions#chemicals#chemistry#Chemistry & materials science news#circular economy#clean energy#cobalt#collaborative#consumer electronics#critical-materials#crust#defense#dept#Developer#development#direction#earth

0 notes