#metal fabricators

Link

Metals have become increasingly important in the construction of the foundation of any structure as industrialization and globalization have increased. It could be tool handles, screws, nuts, or handles from protruding heavy equipment or railings. Every potential called for the utilization of metal manufacturing to ensure long-term sustainability and durability. Metal fabrication is the process of creating machines and structures out of raw metal resources. To make the final product, the process may include burning, cutting, welding, forming, machining, and clustering. To know more visit https://www.rockettinc.com/ or call us at 1 (601) 939-2471.

2 notes

·

View notes

Text

Experience unmatched expertise with Jacksonville's premier metal fabricators. Elevate your projects with precision and reliability.

Trusted Nationwide

ABOUT OUR METAL FABRICATION INDUSTRY

Chancey Metals is a Leader in Metal Fabrication

We are the ideal choice whether you need metal stairs and railing, a balcony rail, a compactor enclosure, or other miscellaneous metals. Our experience and capability make Chancey Metals your preferred partner for a successful project.

For over 35+ years, Chancey has earned a reputation in the industry by providing value, quality, responsiveness, and on-time delivery. We are the leader in the multi-family construction industry in manufacturing and installing all the Division 05 products we fabricate in Jacksonville, Florida, and across the Southern and Mid-West United States.

#chancey metals#metal fabricators#metal fabricators in usa#metal fabricators in fl#metal fabricator in jacksonville florida#metal fabricator in jacksonville fl#metal fabricators jacksonville

1 note

·

View note

Text

Why Choose Custom Fabrication?

Custom fabrication is a desirable alternative for many different types of projects and industries due to its many benefits. The advantage of selecting bespoke fabrication is that you can get solutions that are specifically tailored to your demands. This method allows for greater design, material, and functional flexibility, so you know the final product will meet all of your needs. Because each piece is meticulously crafted to specified specifications, custom fabrication also enables you to achieve higher quality criteria. The ultimate consequence is that the products are robust, consistent, and long-lasting. Additionally, customization allows you to be creative and imaginative, which helps you actualize unique ideas and set yourself apart in a crowded market. Moreover, custom manufacturing may ultimately save costs by optimizing production processes and reducing waste. Its ability to be readily scaled up or down in response to demand makes it a versatile and efficient choice for both small and large-scale manufacturing.

#custom metal fabrication houston#custom sheet metal fabrication#Custom Fabrication#metal fabrication#metal fabricators#welding metal fabrication

1 note

·

View note

Text

Eco-Friendly Advantages of Aluminium Grandstands

Aluminium grandstands are gaining popularity in Australia for various reasons, and one notable aspect that stands out is their eco-friendly nature. As communities and businesses strive to adopt more sustainable practices, the choice of construction materials becomes crucial.

That’s why it’s important to delve into the eco-friendly advantages of aluminium grandstands. By exploring how this material aligns with Australia's commitment to environmental responsibility, it becomes easier to grasp its role in the heavy construction industry for decades to come.

Recyclability

Aluminium is a highly recyclable material, making it a standout choice for eco-conscious projects such as grandstand construction. Unlike some other materials that degrade during recycling, aluminium retains its quality, and the process requires significantly less energy compared to extracting and refining raw aluminium ore.

Australia, being a country with a strong focus on recycling, benefits immensely from the use of aluminium in grandstand construction, contributing to the reduction of waste and lowering the environmental impact.

Durability and Longevity

One of the key environmental benefits of aluminium grandstands lies in their durability and longevity. Aluminium is naturally resistant to corrosion, ensuring that structures built with this material withstand the test of time and harsh weather conditions.

Unlike some traditional materials that degrade quickly, aluminium grandstands require less frequent replacements, reducing the overall environmental footprint associated with constant construction and demolition.

This aspect of the material is even more crucial for events where audiences or participants can get quite rowdy. After all, grandstands are expected to support anywhere from hundreds to thousands of people. Not to mention the equipment and various paraphernalia that might be needed.

Low Maintenance Requirements

Aluminium grandstands also score points for their low maintenance needs. The reduced necessity for ongoing maintenance contributes to a lower environmental impact.

Unlike structures that demand regular painting or sealing, aluminium grandstands maintain their appearance and structural integrity with minimal intervention. This not only conserves resources but also minimises the need for environmentally taxing maintenance activities.

In addition to that, due to the recyclability of aluminium, replacement parts are a lot more accessible. As such, if there is a need to replace certain parts of the grandstand, there will be fewer delays.

Light Weight and Transportation Efficiency

Aluminium's lightweight nature offers logistical advantages, especially during transportation. The reduced weight of aluminium grandstand components translates to lower fuel consumption during transportation, contributing to a smaller carbon footprint.

With Australia's vast landscapes and the need for materials to be transported over long distances, the environmental benefits of using lightweight aluminium cannot be overstated.

Energy Efficiency in Production

Aluminium production, although energy-intensive, has become more environmentally friendly over the years. Many aluminium manufacturers are investing in sustainable practices, such as using renewable energy sources and improving overall energy efficiency.

This shift towards cleaner production methods aligns with Australia's commitment to reducing carbon emissions. As the aluminium industry evolves, the environmental impact of producing aluminium grandstands continues to decrease, making it a more sustainable choice for large-scale construction projects.

Reduction in Heat Island Effect

Aluminium grandstands contribute to mitigating the urban heat island effect, a phenomenon where urban areas experience higher temperatures than their rural counterparts due to human activities and construction materials.

Aluminium, being highly reflective, helps to bounce sunlight away from the structure, reducing heat absorption.

This reflective quality contributes to a more comfortable environment for spectators and lessens the overall impact on local microclimates, aligning with Australia's efforts to create sustainable and liveable cities.

Adaptability and Upgradability

The adaptability and upgradability of aluminium grandstands further enhance their eco-friendly credentials. As sporting and entertainment facilities evolve, the ability to modify and upgrade structures without extensive demolition and reconstruction is a significant advantage.

This adaptability reduces waste and environmental impact associated with constant redevelopment, aligning with Australia's commitment to sustainable urban planning and construction practices.

Conclusion

Aluminium grandstands offer a compelling case for their eco-friendly advantages, aligning with Australia's commitment to sustainability and environmental responsibility. The recyclability, durability, low maintenance requirements, and energy efficiency of aluminium make it a standout choice for large-scale projects.

As communities and businesses across Australia continue to prioritise environmental considerations, the use of aluminium grandstands exemplifies a practical and responsible approach to construction that minimises environmental impact while providing functional and long-lasting infrastructure.

Need high quality fully custom aluminium products and services? Contact us at Custom Aluminium.

#custom aluminium#aluminium products#aluminium fabrication#custom aluminium wa#aluminium services#aluminium#aluminium extrusions#metal fabrication perth#metal fabricators

0 notes

Text

Metal Fabricators in America: A Savior to the Country

The Role of Metal Fabricators in America

Metal fabricators play a crucial role in the United States, contributing to various industries and serving as a cornerstone of the country’s economy. From manufacturing to construction, metal fabricators provide essential services that help drive innovation, create jobs, and support infrastructure development. In this article, we will explore the…

View On WordPress

1 note

·

View note

Text

what is the work of metal fabricators?

Metal fabricators are skilled professionals who play a crucial role in various industries, from construction and automotive to aerospace and manufacturing.

They are responsible for transforming raw metal materials into intricate and functional components that are used in countless products and structures. In this blog post, we will delve into the fascinating world of metal fabricators and explore the vital work they do.

Understanding Metal Fabrication

Metal fabrication is a broad term that encompasses a wide range of processes involved in shaping, cutting, and assembling metal materials to create finished products.

Metal fabricators work with various types of metals, including steel, aluminum, copper, and more.

Their work often begins with raw metal sheets, tubes, or bars, and they use their expertise to transform these materials into precise and custom-made parts.

Cutting and Shaping

One of the primary tasks of metal fabricators is cutting and shaping metal materials.

They use a variety of tools and techniques, such as shearing, laser cutting, and plasma cutting, to trim and shape metal into the desired dimensions.

This precision cutting ensures that the fabricated components fit perfectly into the final product.

Welding and Joining

Welding is a fundamental skill for metal fabricators. It involves fusing metal pieces together using intense heat to create strong and durable bonds.

Metal fabricators use different welding methods, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and stick welding, depending on the specific requirements of the project.

Welding is critical in constructing frameworks, pipelines, and various metal structures.

Forming and Bending

To achieve specific shapes and designs, metal fabricators use processes like bending, rolling, and stamping. They manipulate metal sheets or bars to create curves, angles, and contours according to the project's specifications.

This expertise is crucial in manufacturing items like custom brackets, panels, and enclosures.

Assembly and Finishing

Metal fabricators are responsible for assembling the fabricated parts into the final product. This may involve attaching various components, such as fasteners, hinges, and brackets, to ensure everything functions as intended.

Additionally, they often perform finishing tasks like grinding, sanding, and painting to enhance the appearance and performance of the metal components.

Quality Control

Ensuring the quality of fabricated metal components is a vital part of a metal fabricator's job. They use precision measuring tools and inspection techniques to guarantee that every piece meets the required standards and specifications.

Quality control is essential to prevent defects and ensure the safety and reliability of the final product.

Adaptability and Problem-Solving

Metal fabricators often encounter unique challenges and must be highly adaptable problem-solvers. They may need to work with a wide range of metals, accommodate design changes, and find innovative solutions to unexpected issues that arise during the fabrication process.

Conclusion

Metal fabricators are the unsung heroes behind many of the products and structures we encounter daily. Their work is characterized by precision, craftsmanship, and a deep understanding of metalworking techniques.

Whether it's constructing buildings, manufacturing machinery, or creating custom metal components, the work of metal fabricators is integral to modern industry and innovation.

The next time you see a sleek steel sculpture or drive over a well-constructed bridge, remember the skilled hands of metal fabricators that made it all possible.

0 notes

Link

There’s a difference between an ordinary and a great metal fabrication engineer. Find an experienced engineer with great metal fabrication skills.

1 note

·

View note

Link

#Metal Fabrication#welding services#maaching services#metal fabricators#metal fabrication services#steel fabrication#welding

0 notes

Text

An 18th-century embroidered panel hangs on the twenty-foot-high walls, which cove seamlessly into the ceiling.

The Los Angeles House: Decoration and Design in America's 20th-Century City, 1995

#vintage#vintage interior#1990s#90s#interior design#home decor#living room#round table#orange#metallic#fabric#fireplace#antique#rug#lighting#California#Spanish#style#home#architecture

618 notes

·

View notes

Link

In Mississippi, there are many different methods used to fabricate metal. However, not all of these steps are necessary for the production of a certain product. According to the design and other application requirements, different ones may be required. Specialized metal manufacturing is useful in this situation. It helps metal fabricators to select the ideal metal fabrication process for the precise manufacturing of the product. To know 3 Key Factors That Make Custom Metal Fabrication Superior to Stock Fabrication visit https://www.rockettinc.com/ or call us at 1 (601) 939-2471.

#Mississippi metal fabricators#Custom metal fabrication#Metal fabrication in Mississippi#metal fabrication#metal fabricators#best metal fabrication procedure

1 note

·

View note

Text

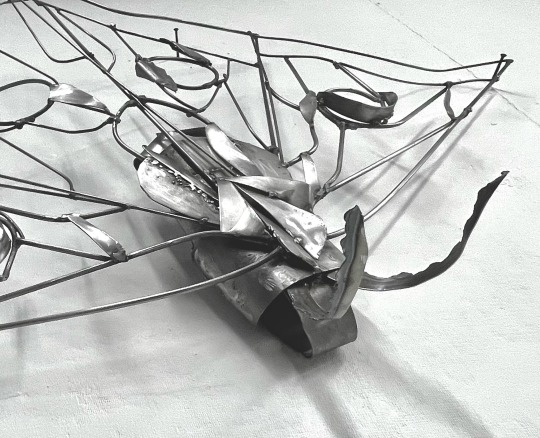

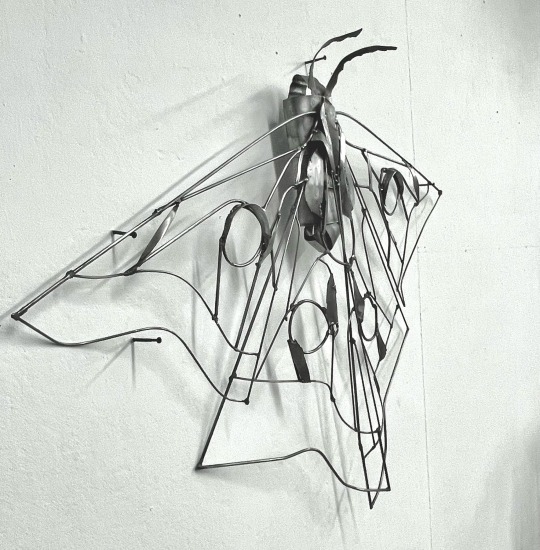

Metal moth COMPLETE!

#metalworking#welding#metal#art#artists on tumblr#artists of tumblr#sculpture#metal fabrication#moth#moon moth#my art#this was for a class and I’m actually pleasantly surprised with how it turned out#yippe

352 notes

·

View notes

Text

Is Aluminium Better For Building Boats Than Steel?

Aluminium has a reputation for being soft and malleable, but it has been used to build boats for a while now. With this being the case, it stands to reason that the material can be tough and durable, as well. This reflects the versatility of aluminium in a way that brings a simple point home: It’s perfect for building boats.

Aside from its versatile properties as a building material for constructing boats, however, there are a lot of other reasons why aluminium is often a popular choice for this purpose.

Why Metal Boats Make Sense

Before delving into the particulars that make using aluminium as a material for building boats a sensible course of action, some context about metal boats is needed. Simply put, metal has allowed for the building of vessels that are larger, more durable, and faster than anything that came before them.

Wooden ships could be big, but they were limited by several things, namely; material size, density, lifespan, and tensile strength. Organic materials simply could not beat the properties of metal in terms of qualities that are highly prized today.

On that note, you can’t just build a boat using any kind of metal. It took centuries of refining alloy combinations and engineering concepts to get to the point where modern ships are actually economically viable. Shipbuilding is expensive, after all, and those spending money on it want to make the most of their investment.

This takes us to today’s current state in material options. Either metals like aluminium are used on their own or they are combined with other metals for specific purposes. From there, they are then used in conjunction with something like steel to add extra sturdiness without making too much sacrifice in terms of weight.

How Aluminium Makes Excellent Boats

As already mentioned, it took decades of experimentation to reach today’s quality of material combinations and treatment for shipbuilding. This actually comes back to the reason why aluminium is such a popular option for building boats and for helping to build large ships.

Modern shipping is a combination of numerous factors to make them work, but let’s focus on only a few. There’s the engine system, providing the propulsion. The design, which makes it easier to actually cut through the surface of the water. Then there’s the materials, which will need to accommodate the conditions applied by the previous factors.

Taking all of that together, we arrive at the reasons why aluminium is so valued in the industry. It’s tough enough to withstand constantly going against resistance from water, light enough to reduce power consumption, and versatile enough to meet complex designs.

To really appreciate these aspects, however, let’s take a look at them in more detail:

Light is good - Although there are some points of contention to this assertion, generally speaking, the lighter the vessel the better it is. Obviously, this would depend on what the vessel will be used for. Tankers, for example, need to be a bit heavy in order to maintain buoyancy while empty but not too heavy to sink when full.

Aluminium can solve this issue with smaller boats or even ships that have more complex designs. It lightens the vessels without compromising the reasons for them to stay afloat.

Material strength - Regardless of which body of water a vessel needs to traverse, they will all resist motion. The faster the vessel goes, the more resistance it will face, which will cause stress on the material. Aluminium can be made tough and thick enough to actually withstand this stress.

Of course, there are still some limitations. You can’t make an entire tanker just out of aluminium. Combining it with other alloys though? Now, that’s doable.

Extremely forgiving - One of the biggest advantages of aluminium is just how easy it is to work with. As long as you have competent personnel who know how to handle it, you can make pretty much anything out of it. This is important in boatbuilding due to how complex the designs can be. As such, you need a material that won’t put up too much of a fight.

Cost-effective - Tying up all of those neat features together, aluminium also doesn’t cost as much as alternative materials to buy and use. This then makes building aluminium boats cheaper without compromising the quality of the final results.

Need high quality fully custom aluminium products and services? Contact us at Custom Aluminium.

#custom aluminium#aluminium products#aluminium fabrication#metal fabrication perth#metal fabricators#custom aluminium wa

0 notes

Text

deadliest couple in Thedas u.u

(patterns are form here!)

#i got lazy with the shading lol but i had fun playing around with patterns!#also this really made me realise again how badly i need to practice fabrics & metallics lolol#but anyway! have a they <3#theyre such a pretty couple fr#ari should be taller/josie shorter lol but that made the framing weird#my art#my ocs#oc: ari adaar#josephine

119 notes

·

View notes

Text

thinking about puppet tattoo parlors. A wall covered in so many different thread colors to choose from - swatches of different types of stitch for different textures / effects. modified handheld sewing machines for tattooing with multiple settings for the different stitches. individual needles + embroidery thread as stick n pokes...

#THINKING SO HARD ABOUT THIS#wouldnt this be cool though???#cause i was thinking fondly of tattoos and went 'hm. how would a puppet do this?'#cause ink can bleed in fabric. it can scrub out. the lines wouldnt be as clean and i just dont think it would really Stick?#but EMBROIDERY! STITCHES! COOL SEWING GUNS INSTEAD OF TATTOO MACHINES!!!#and now im wondering Could They Remove Their Tattoos?#it would probably be pretty invasive!#hold on im doing research real quick#yeah looks like they'd need to lift their felt/fleece/skin to get at the back of the stitches#then sew the skin back together afterwards...#so to them tattoos would be just as permanent as they are to Us! because who wants to go through That!#im having a grand ol time imagining the Range their tattoos would have#textures! endless colors! glitter thread! metallic thread! wool! cotton! polyester! glow in the dark! scratch n sniff!#that last one was a joke.#imagining someone with an entire detailed forest scene carpeting their back... it has Depth...#absolutely unprompted#puppets#sundown summer is getting a motherfuckin tattoo if its the last thing i do#resisting the urge to just litter every puppet that i know of with this idea#YOU get a tattoo and YOU get a tattoo and YOU-

123 notes

·

View notes

Text

Hello @thelien-art I saw your DTIYS and I was instantly inspired to do a quick celebrian x elrond because it's super cute and also I've... never actually drawn them together? blasphemy

This was super fun but shading clothing defeated me. I definitely tried to keep the really cool flowing shapes you had for the hair and clothing folds. I made the bg pink whilst sketching and then committed too hard, now it's shojou romance time

ft. live king reaction below the cut

#silmarillion#elrond#celebrian#celrond#shading the hair was so much fun ngl#clothing tho#f me i cant do clothing. metals? np! fabric??? big f#im sorry elrond u especially suffered from this i just could not....................#anyway thelien i discovered ur art via seeing these dtiys so! thanks for doing it now i have another good silm artist to follow#srsly tho kudos on the fabric love the drape love the colors cannot for the life of me replicate easily#inktober#artober...#i didnt feel like doing yesterday so... today two characters....even if its for a dtiys and not inktober....#also her other hand her other hand was hell to do i think its still. too small.... f... anatomy..................#anyway this was very fun

126 notes

·

View notes

Note

questions about your green cotton braided rug project: can you elaborate on what you mean by double folding the cotton strips?

i adore the look of your rug. do you think an amateur (i.e. myself) could create something similar with a sewing machine? i can certainly poke around the internet for patterns/instructions, but im not sure how to judge the difficulty level of your project

Thank you!

If you've seen double folded bias tape, the strips are folded just like that. I'm pressing it in half, and then tucking the two edges in, so I've got a tube with the raw edges inside that's 1/4 the width of the strips I tore. I'm also tearing the yardage first and then sewing the strips together by machine, before I fold them.

Yeah, I think you could use a machine, at least for the tubes! A little topstitch along the edges would hold them together, or perhaps a tiny zigzag riiiight along the edge would be more inconspicuous. A zig zag that catches the two folded edges on one side and then doesn't on the other size.

Definitely do samples first. Always do samples! I can't test that idea because my machine doesn't do zig zag.

You'll probably still need to whipstitch the braids together from the underside, but that part is much faster than sewing the tubes. And be sure to iron it after adding every round, so the ends don't get dished!

#there are little metal thingies specially made for folding strips like this and I have some but they're meant for much thicker fabric#and didn't work with this cotton so I'm just folding it by hand and it's fine#ask#sewing#rugs#braided rug

99 notes

·

View notes