#props

Text

16K notes

·

View notes

Text

Yummy sweet weapons

#artists on tumblr#illustration#props#candy#weapons#I have to feed my portfolio...I never draw props#I had to if I want a decent job lmaoo

4K notes

·

View notes

Text

Sometimes the prop department builds the most intricately beautiful piece of sci fi equipment you’ve ever seen with working blinking lights that have secret messages in Morse code and sometimes they hand you a thermometer to use as a tricorder stylus.

1K notes

·

View notes

Text

Star Trek Set Tour 5/?: Sick Bay

#star trek#star trek tos#the original series#film#1960s#film set#set design#leonard mccoy#doctor mccoy#bones#props#retro futurism#sci fi#locations#katpost

1K notes

·

View notes

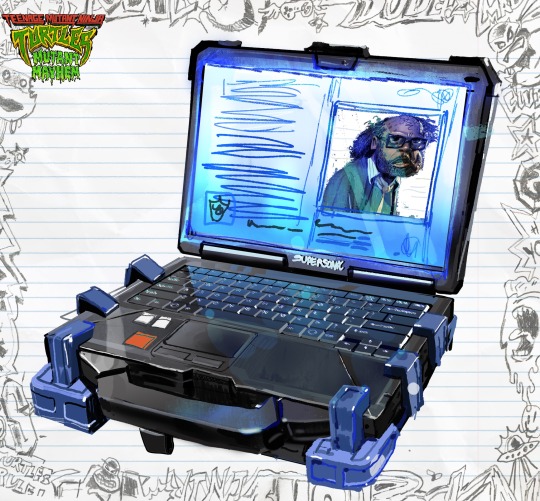

Text

yuri.nosho

9K notes

·

View notes

Text

bloody outfits from hannibal (NBC)

#I CANT STOP LOOKING THESE UPPPP I NEED TO SLEEEEO but im so obsessed theyre so cool#i love scrolling through hannibal props every now and then like a little treat#hannibal#hannibal props#will graham#hannibal nbc#mads mikkelsen#hugh dancy#blood#hannibal bts#props

23K notes

·

View notes

Text

Realistic Pokeball made by Soupcan13creations

#pokemon#nintendo#art#anime#gaming#video games#pokeball#props#cosplay#crafts#handmade#gameboy#gba#ds#3ds#switch#nintendo switch#pokemon go#pokemon scarvi#90s#retro#nostalgia#nostalgic#steampunk#aesthetic#gifts#merch#artists#90's#nineties

981 notes

·

View notes

Photo

Colin Farrell on the set of Alexander, 2004

#movies#BTS#colin farrell#alexander#cinema#films#set#sets#props#costume design#smoking#cigarette#blood#bloody#actor#u

2K notes

·

View notes

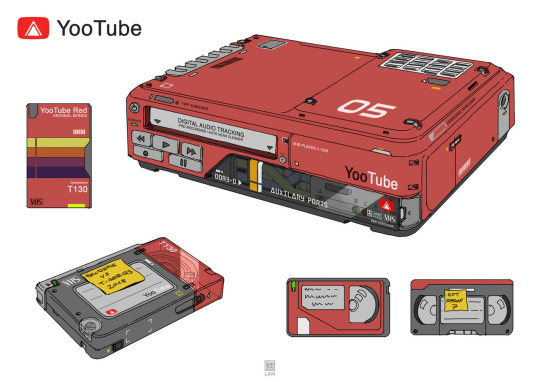

Text

Prop paintings for TMNT mutant mayhem , the guns are from a cut longer version of the ice cream heist and the tools are from an old version of the chop shop fight. the fish are somewhere in the background of the no digity scene

#illustration#artists on tumblr#kellan jett#art#drawing#painting#concept art#sketchbook#prop design#props#the art of animation#animation art#nickelodeon#tmnt mutant mayhem#mutant mayhem#teenage mutant ninja turtle mutant mayhem#teenage mutant ninja turtles#visdev#visual development#conceptart

995 notes

·

View notes

Text

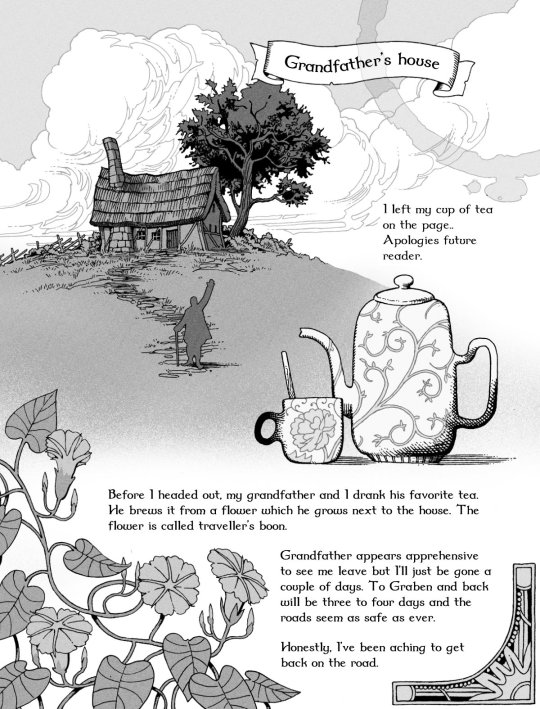

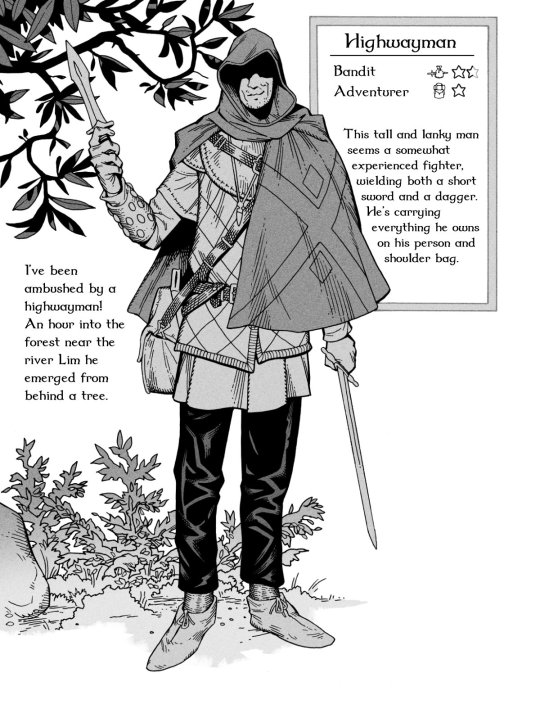

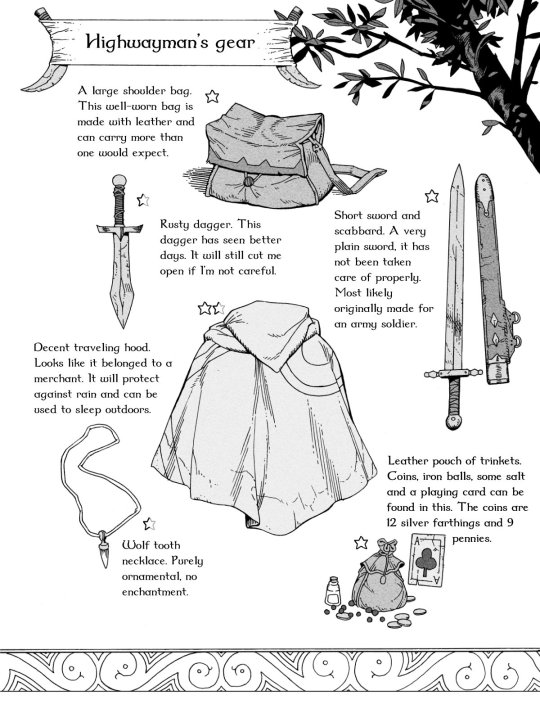

8 journal pages from a fantasy adventure

I've done these as a test to see what an entire book could look like ✨

Kickstarter link

1K notes

·

View notes

Text

280 notes

·

View notes

Text

Emma Porteous "Pvt. Hudson" costume from Aliens (1985)

567 notes

·

View notes

Text

This exquisite pillowcase, adorned with intricate embroidery and lace detailing, was originally seen in Victoria, where four of them could be seen on the Queen’s bed.

Two of them were then spotted in the 2018 adaptation of Vanity Fair in the bed of Lady Matilda Crawley.

Fast-forward to 2019 and this same pillowcase could be seen in Gentleman Jack, making a luxurious addition to Ann Walker’s bed.

In 2021 the same pillowcases were reused on the set of The Pursuit of Love, providing a touch of elegance to Linda Radlett’s bed.

In 2023, they were seen in Tom Jones in Sophia Western’s bed.

Most recently, for a split second they were spotted again in the new trailer for the third season of Bridgerton, where a very determined Penelope Featherington wakes up between them.

Costume Credit: bellcs

Follow: Website | Twitter | Facebook | Pinterest | Instagram

#bridgerton#tom jones#the persuit of love#gentleman jack#vanity fair#victoria#props#costume drama#period drama

255 notes

·

View notes

Text

I...My notification are exploding idk where the fuck do you all come from i feel i have summoned people from another dimension hahaha,

To thank you all, here one of my favorite shoot, i never did pics like because i was more confident with full armor cosplay (with helmet/mask) and i never had that much seltrust, but i was feeling confident with my friend this time <3

#cosplay#nicholas d. wolfwood#cardboard#wolfwood#vash the stampede#trigun 98#trimax#trigun#trigun stampede#carboardcosplay#cosplay props#props#Instagram

856 notes

·

View notes

Text

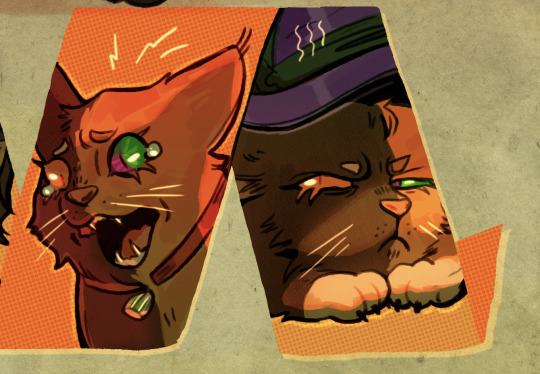

detailed character sheet Family Portrait of Ruairidh & Aira Sgak for @king-ghidorah. What a beautiful family!🖼️

🖼️more commission info in source!🖼️

#anonbeadraws#digital#digital art#commission#dnd commission#dnd#digital commission#artists on tumblr#digital illustration#cat#orc#weapon#props#wizard#magic

681 notes

·

View notes

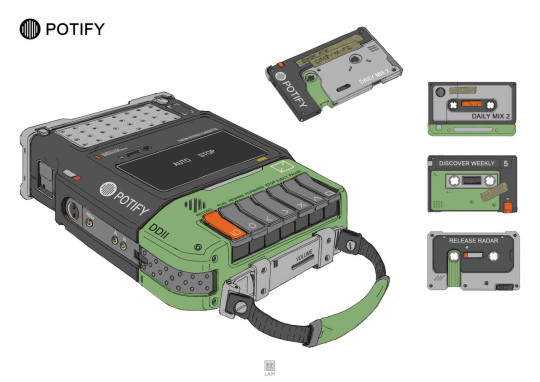

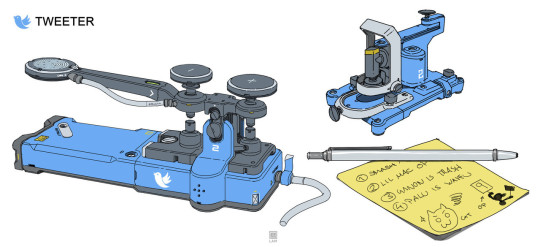

Text

Prop practice

310 notes

·

View notes